1972-2022: 50 years MOBA – a reason to celebrate

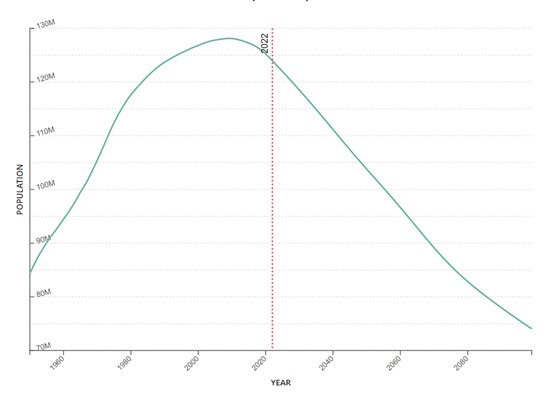

2022 is a significant year for MOBA – we celebrate the 50th birthday of this impressive company.

50 years – that are 5 decades with powerful innovations, exciting developments and a lot of new solutions for machine automation. 50 years ago Paul G. Harms founded the company in the garage of his house – today MOBA is one of the most important machine automation experts worldwide. But some things did not change during this long time: As it was in the beginning, also nowadays it is the people that take the center stage – staff, customers and fans. Their passion for machines, technology and innovation is what links all of them.

The roots

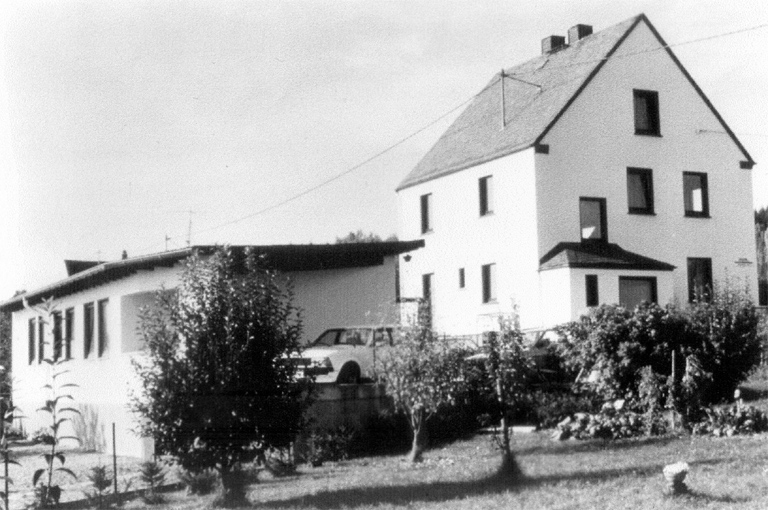

It was in 1972 that Paul G. Harms founded an engineering office for machine automation in Steinbach, which is 10 km north of Limburg, where MOBA’s headquarters is located today.

An interesting fact is the registration fee, which was 50 Pfennige, roundabout 25 Euro-Cents.

Manifold successes

MOBA’s success story had its beginning with the levelling controller of series Grade Line G 176 & S276, followed by the worldwide known MOBA-matic Controller and some integrated systems for OEMs. Also MOBA’s Big Sonic-Ski is a success story that started long ago and lasts until today. It works reliably on many machines and helps to improve roads all over the world. Another important branch in the first years was weighing technology for agriculture followed by weighing systems for cranes and lifters.

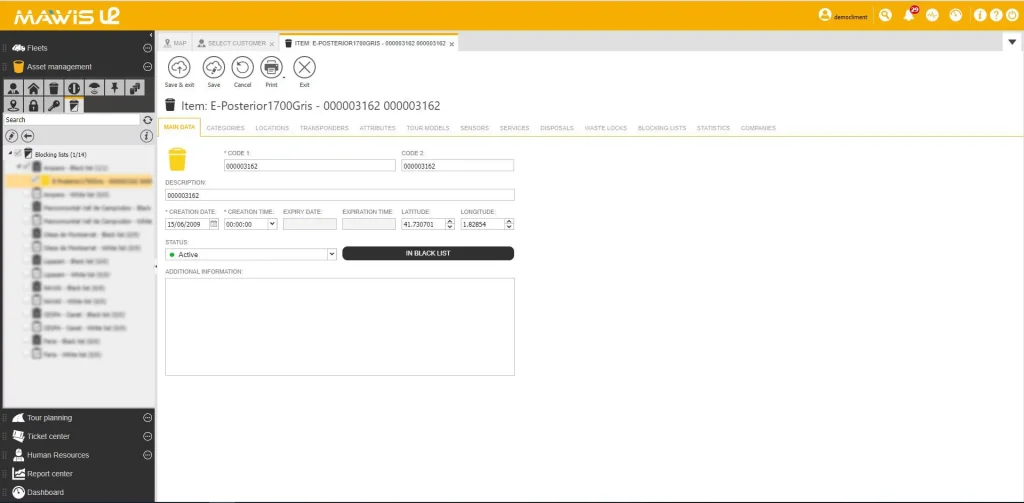

Some of the most sophisticated technologies on the market are made by MOBA, for example DMS-systems for weight control in waste disposal, precise ultrasonic technology for distance control, laser receiver and sender for levelling systems, grade and slope sensors for different applications and systems for asphalt quality control and layer thickness measurement.

All these products and systems are not only working on road construction machines, but also many MOBA products and solutions for crane and lifters, earthmoving and the waste industry help to improve processes and results.

Worldwide expansion

In parallel with technologies and solutions, MOBA grew as a company with more and more people working for MOBA. With many subsidiaries in Germany, Europe and worldwide, a growing global network of distributors and a deep market penetration MOBA gained more and more importance on the markets worldwide. MOBA still develops its technologies in-house as well as in local development departments in its branches in the US, China, India, Italy and Spain. Furthermore, the high manufacturing depth guarantees high quality products.

So the company developed from a small “one-man-show” to an important global player. And many people – customers, partners and also staff accompanied MOBA for many years, as did Vice President (Development) Alfons Horn, who works with high engagement since almost 40 years for MOBA now and who contributed to many path-breaking ideas and products.