Another international Racetrack build with a MOBA Big Sonic Ski leveling system

The Pertamina Mandalika International Street Circuit, also known as Mandalika International Street Circuit for commercial purposes, is situated in the Mandalika resort area of Lombok island, which is part of Indonesia’s West Nusa Tenggara province. The circuit was inaugurated in late 2021 and hosted rounds of the Asia Talent Cup and Superbike World Championship, followed by Grand Prix motorcycle races in 2022. The project encompasses 120 hectares and includes the development of hotels and other amenities. The circuit is designed with wide run-off areas and is considered a street circuit as parts of it may be opened for normal traffic to access new resort facilities in the future.

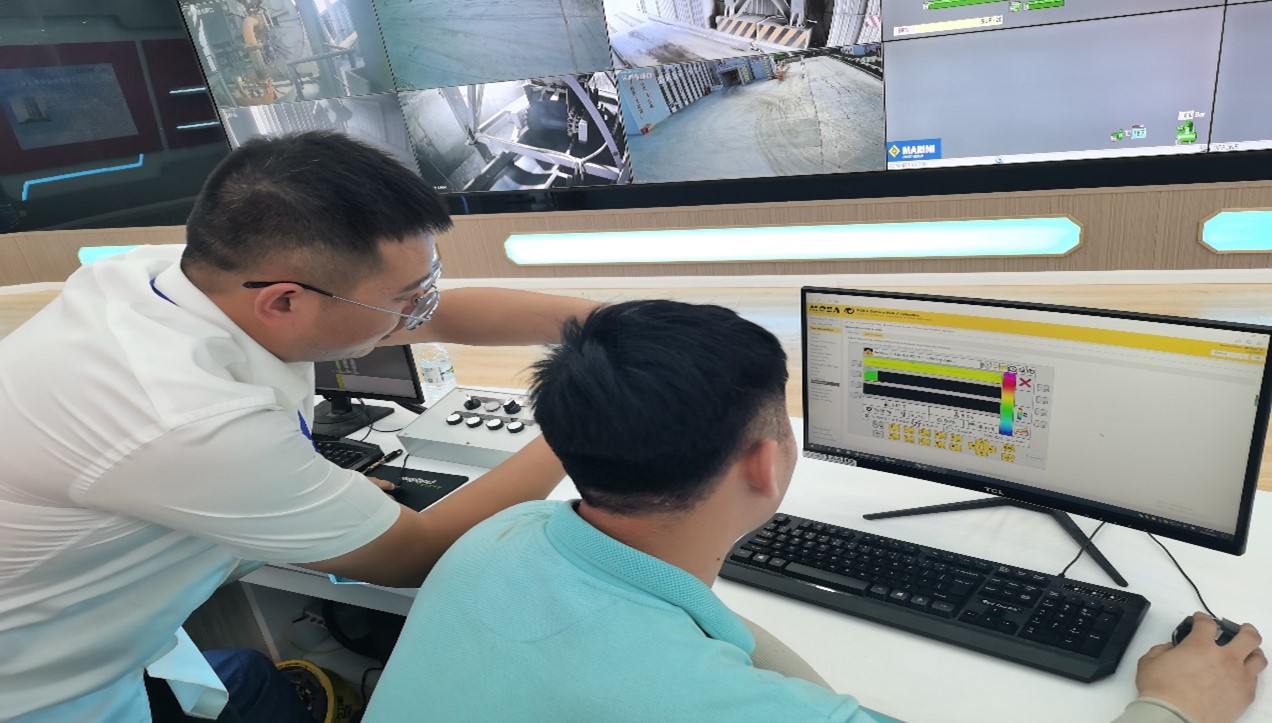

The MOBA Big Sonic Ski is a state-of-the-art leveling system that can be used for a wide range of construction applications, including race track construction. With its advanced sensor technology and precise control capabilities, the Big Sonic Ski can ensure a level and even surface for the entire length of the track. This level of accuracy is crucial for maintaining optimal safety and performance conditions for race cars and their drivers.

Equipped with a Big Sonic Ski on each side of the paver, the local paving team is able to achieve unparalleled performance and seamless smoothness of the road.

In addition to its leveling capabilities, the Big Sonic Ski can also help reduce construction time and costs. With its real-time monitoring and feedback capabilities, the system can detect and correct any deviations in the surface level immediately, eliminating the need for costly and time-consuming rework.

Overall, while it is up to each race track to decide which leveling system to use, the MOBA Big Sonic Ski can offer a range of benefits for construction projects, including improved safety, performance, and cost-effectiveness.