XSite Easy 2.0

Xsite Easy - it was never more easy to become independent in your excavation operations.

Xsite® EASY excavator guidance system removes the need for manual grade checking and jumping on-and-off the machine. Xsite® EASY enables doing the work correctly the first time, avoiding over- and undercuts. Work with slopes and planes with centimetre accuracy without unnecessary interruptions. The easy-to-use system guides the operator in achieving the desired depth and/or inclination via easy-to-follow, real-time graphics.

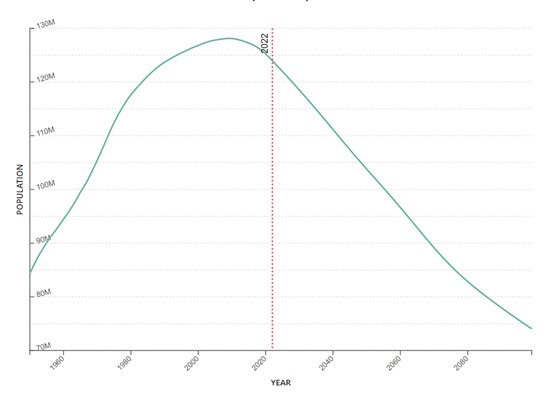

Xsite® EASY can be installed to any excavator. Whether you drive a rubber tracked mini excavator, a medium sized wheeled excavator or a large, tracked excavator, Xsite® EASY will help you at every step of the way. Support for two-piece booms and a variety of tilt rotators gives you countless possibilities to boost your work as a number of tasks can be handled with only one machine. The main benefits are illustrated below.

Benefits of Xsite EASY

- Work with Foundations: Measure distances, heights and slopes with centimetre precision and maximize your productivity.

- Underwater Working: In addition to depth and distance, the Xsite EASY system displays your bucket’s position in real-time. With Xsite EASY you’ll always know in which position your bucket is, even if you don’t see it.

- Level Out Flat Pads: Level out and prepare large flat areas with speed and accuracy. All from the comfort of your excavator cabin

- Excavate Trenches / Slopes: Take advantage of the easy-to-use laser receiver and achieve the correct grade and slope on the first go

A new display with new opportunities - Xsite easy 2.0